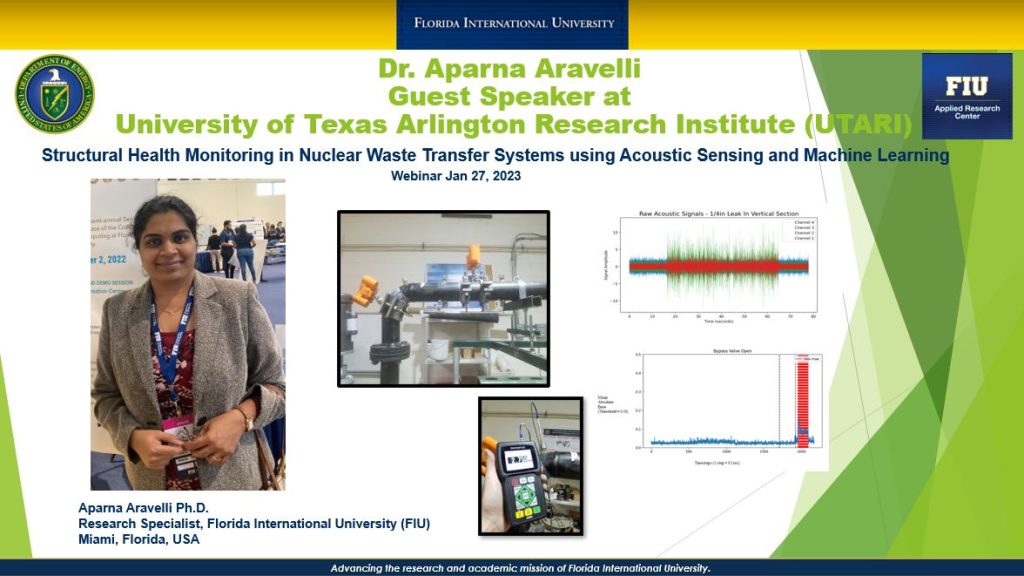

Dr. Aravelli is a Research Specialist and an adjunct faculty at Florida International University (FIU). Her research and industrial experience span multidisciplinary areas of engineering that include sensors, robotics, building energy systems modeling, engine emissions, optimization, and structural health monitoring. She recently presented her research on Structural Health Monitoring in Nuclear Waste Transfer System using Acoustic Sensing and Machine Learning at the University of Texas Arlington Research Institute (UTARI). The abstract of the presentation is below.

Abstract:

Structural Health Monitoring (SHM) is a major concern in the Department of Energy’s (DOE’s) nuclear waste sites due to the associated risks. Of particular interest are the metallic tanks and transfer systems used to store and transport the High-Level Waste (HLW). This talk will provide an overview of three sensing technologies used to detect the material erosion-corrosion and anomalies/faults in the HLW transfer pipelines. Non-destructive testing (NDT) based acoustic sensors have been experimentally evaluated in flow loops transferring simulated nuclear waste mixtures. The flow loops have been custom designed, constructed and tested at our facility by generating accelerated erosion and caustic corrosion in 3-inch and 2-inch carbon steel pipe sections as an indicator of the wear due to the waste transfer process. Sensing modalities include wave guided ultrasonic sensors, fiber optic electroacoustic sensors and a patented ultrasonic thickness/mass loss coupon technology developed by the Savannah River National Laboratory (SRNL) scientists. The experimental data captured was analyzed by the researchers manually in the first stage of the research effort. In the second stage, an automated real-time monitoring system was developed. The data obtained from experiments is used to build, train and test machine learning models to automate the process. Images and numeric data have been used to develop neural network-based machine learning models to predict material erosion/corrosion and to automate the anomaly/fault detection in pipelines. This work indicated that the DOE, nuclear industry and oil, gas & petroleum industry can benefit from the adoption of these SHM technologies to facilitate real-time infrastructure monitoring thus reducing maintenance costs, risks and ensuring safety.