Sponsor – DOE

This task supports US DOE EM-13 in developing plans for improving active remediation systems to improve performance while lowering resources (money, GHSs, energy) used. The initial effort identified specific improvements to the SRS A/M Area groundwater remediation system with expectation that it would apply to many “pump and treat” systems across DOE.

Under “Sustainable Remediation” sustainability metrics are identified and included into environmental management decisions.

The analyses applied to subsurface and surface contamination and supplement traditional risk paradigms which help to develop interim and final remediation end-states and improvements from upgrades to aging components and optimization of operations.

US EPA identifies 6 core elements of Green Remediation in its primer that are considered when designing and implementing cleanup measures:

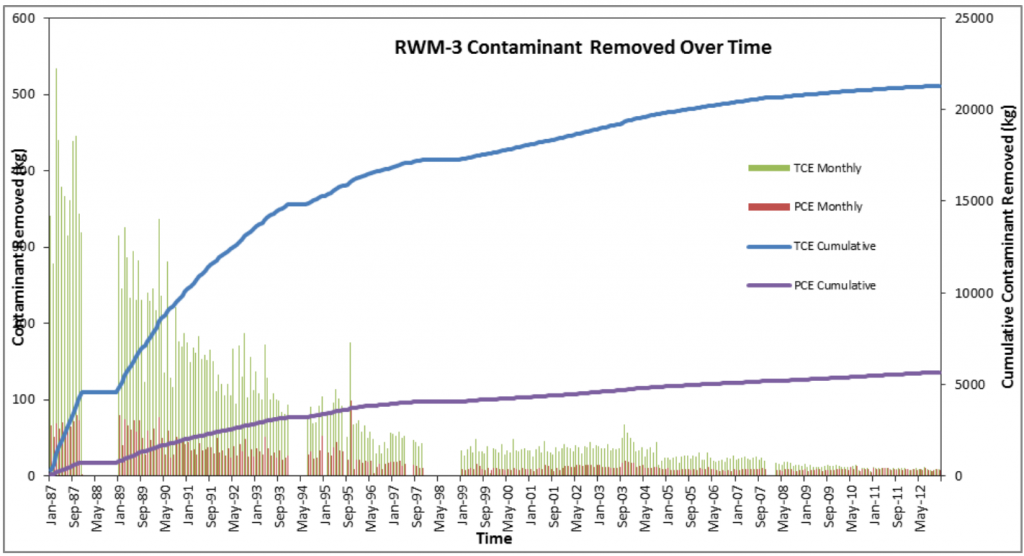

Fig. 2. Recovery of TCE and PCE from 1987 to 2012 from Recovery Well #3 as indicator for the need to optimize pumping from every well.

Accomplishments:

1. Green and Sustainable Remediation Practices, Tools and their Application at DOE Office of Environmental Management Sites

2. Baseline Summary Report for Sustainable Remediation Options for M1 Air Stripper at DOE SRS

3. Sustainability Analysis for the M1 Air Stripper and Pumps of the M Area Groundwater Remediation System at DOE SRS

4. Green and Sustainable Remediation Options for the M Area Groundwater Remediation System at SRS

5. A preliminary Green and Sustainable Remediation Analysis of the M1 Air Stripper at DOE’s Savannah River Site, Waste Management, Mar. 2016.

Sustainability analyses resulted in these 4 primary recommendations:

1. Utilization of a solar photovoltaic system for powering the A/M Area groundwater remediation system.

2. Further analysis to determine an optimal speed for the blower motor that is sufficient to run the countercurrent stripper and removes the volatile organic contaminants to below the 1 ppb required.

3. Groundwater modeling analysis to optimize the pumping rate for each recovery well and for the entire system that provides hydrologic containment and maximizes the concentration of contaminants pumped to the stripper with lower total groundwater and air flow rates.

4. Replacement of groundwater pumps when they fail with lower power pumps that match the required pump rate of the recovery well (e.g., additional lower powered 1-5 HP pumps).