Sponsor – DOE

FIU’s Applied Research Center (ARC) is supporting the U.S. Department of Energy’s Hanford Site by developing robotic technologies for the evaluation of Tank 241-AY-102 and other similar tanks.

Tank waste has recently been discovered in the annulus of AY-102. Inspection tools are needed to isolate and pinpoint the source of the material entering the annulus. These tools will need to provide video feedback so that an assessment can be made regarding the structural integrity of the tank bottoms.

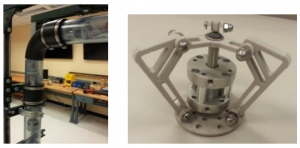

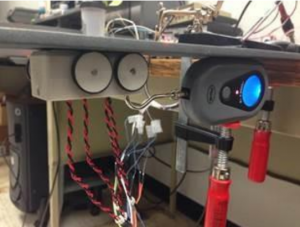

Inspection tool mock-up testing (L); gripping mechanism (R).

There are three paths of access to the tank floor: 1) through air channels in the tank refractory pad, 2) through a 4-in annulus air supply pipe which travels to the central plenum, and 3) through a 6-in leak detection pit drain from the central sump. Engineers at Hanford have investigated potential inspection tools from the commercial industry which can traverse through any of the three access paths, but have not found viable tools.

The objective of this task is to develop inspection tools that can provide visual feedback of the DST floors by utilizing lessons learned from previous projects, and to gain an understanding of limitations from other potential tools. FIU engineers will work directly with site engineers to develop alternative designs based on specified performance criteria.

Specific subtasks include:

Testing of the prototype of the slot inspection tool.

Accomplishments:

Sponsor – DOE Nonmetallic materials are used in U.S. DOE’s Hanford Site Tank Farm WTS and include the inner primary hoses in...

Sponsor - DOE The ability to monitor the interface between liquids containing suspended solids and settled solids in HLW tanks...

Sponsor - DOE FIU’s Applied Research Center (ARC) is supporting the U.S. Department of Energy’s Hanford Site by developing...