Waste and D&D Engineering and Technology Development: FX2 Advanced Fogging Technology Testing and Evaluation

Sponsor – DOE-EM

The objective for this task was to test and evaluate the FX2 Advanced Fogging Technology, developed at INL, for potential implementation at the SRS 235-F facility to better address potential airborne contaminants; this technology is relevant to D&D activities at other DOE sites and internationally. The FX2 fogging agent is a proprietary mixture of water, latex paint, glycerin, and sodium lauryl sulfate. It displayed promising results at fixing potential airborne contamination such as dust and lint via cost effective, remote application methods during initial testing at INL in 2014. FIU, in collaboration with INL and SRNL, expanded on these initial results by testing and evaluating the fogging agent at FIU. INL is also collaborating on related research with UK’s National Nuclear Laboratory (NNL).

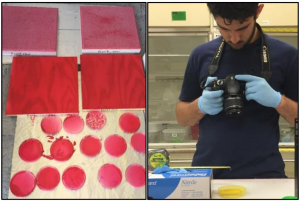

Samples from FX2 fogging test (left). DOE Fellow imaging samples for analysis (right).

The testing of the FX2 Advance Fogging Technology at FIU included tests to evaluate the following:

- Ability to fix loose contamination to different types of surfaces (glass, concrete, steel, wood, and plastic) and adhesiveness to the surface.

- Ability to cover locations both within and outside of the direct line-of-sight of the fogger.

- Capacity to knockdown airborne particulates.

- Characteristic properties of the product:

o Burn rate (ASTM E84)

o Flammability (ASTM D3065)

o Viscosity (ASTM D2196)

o Surface Tension (ASTM D1331)

o Density (ASTM D1475)

- Reactivity to flame and heat sources.

- Ability to shield against an alpha emitting point source.

- Coverage of surface area, as quantified with ImageJ software which analyzes color contrast to determine coverage of the product.

- Correlation of radiation shielding to the coverage results.

Accomplishments:

- The technology demonstration was performed from March 30 to April 3, 2015. The selected technology was demonstrated at the Applied Research Center (ARC) Technology Testing & Demonstration Facility in Miami where an existing hot cell mockup facility was modified to meet the objectives of the demonstration

- Results of the testing and evaluation, including photographs, videos and a Technology Demonstration Evaluation Report, are available on the D&D Knowledge Management Information Tool (www.dndkm.org).

- Results indicate that the technology achieved the objectives of this evaluation, demonstrating an effective means of fixing loose simulant contamination and adhering well to multiple types of surfaces, thereby protecting workers and minimizing the risk of spreading contamination during D&D activities.