Chemical Process Alternatives for Radioactive Waste: Evaluation of FIU’s Solid-Liquid Interface Monitor (SLIM) for Estimating the Onset of Deep Sludge Gas Release Events

Sponsor – DOE

The ability to monitor the interface between liquids containing suspended solids and settled solids in HLW tanks has multiple, important applications at Hanford including:

Fig. 2. Deployment platform with gooseneck heel

Fig. 1. 3D profiling sonar and controller

- Measurement of the height of HLW solids added to double-shelled tanks to ensure it is below the critical value determined from a safety basis;

- Imaging in single-shelled tanks to support pump emplacement to minimize plugging potential;

- Rapid imaging of the floors of mixing, conditioning tanks to ensure effective mixing and retrieval of waste by Pulsed Jet Mixers (PJMs);

- Imaging and volume estimation of settled solids in HLW tanks to monitor for hydrogen gas retention in deep sludge layers as seen by increased volume (height) of waste.

FIU’s Applied Research Center (ARC) has developed a near-real-time solid-liquid interface monitor (SLIM) able to be deployed into 1 million gallon HLW tanks at Hanford.

SLIM consists of:

- A profiling 3D sonar;

- A mechanical system for deployment of the monitor into HLW tanks.

Fig. 3. Air bladder with metal weights underneath taped to a plastic lid.

SLIM is capable of:

- Functioning in high-nuclear radiation in HLW;

- Functioning in highly caustic solutions (pH>14);

- Being deployed through a 4-inch riser at the top of

the HLW tank;

- Operating from many meters to as low as 10 inches above the settled solids layer;

- Measuring the interface elevation across the sonar’s field of view and mapping the surface;

- Measuring the change in elevation of surface (hence the volume of waste under that surface) over time in the tank;

- Measuring the height of the solids layer to 1% resolution (i.e., 1 cm for sonar 1 m above surface: 3 mm for sonar 30 cm or 1 ft above the surface).

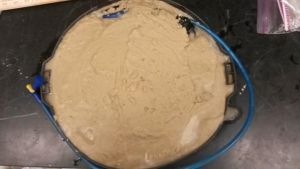

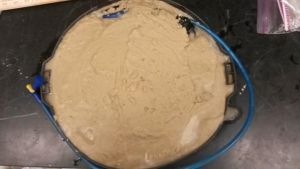

Fig. 4. Same air bladder covered with paver sand to create object to be imaged by the 3D sonar.

Benefits:

Benefits of developing the Solid-Liquid Interface Monitor are:

- Improves HLW retrieval efficiency;

- Assists in maximizing the utilization of available tank space in the double-shell receiver tanks;

- Protects workers and minimizes dose by remote operation of monitoring activities;

- Reduces environmental risk by ensuring that HLW tanks cannot be overfilled.

Accomplishments:

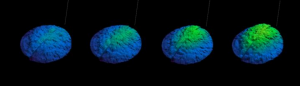

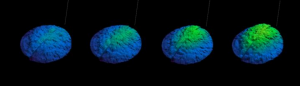

Fig. 5. Four 3D sonar images: no air in bladder (left); after successive air additions in the next 3 images.

- Completed several prototypes of SLIM and tested against functional requirements for in-tank deployment;

- Mechanical, instrumentation and control design of system follow Hanford specifications;

- Performed system structural Finite Element Analysis (FEA) of the deployment platform;

- Completed system in-house fabrication;

- Completed 25+ tests on SLIM or the sonar alone and demonstrated that it met the Hanford site’s needs for 4 different applications in HLW tanks (described above).